- Elkem

- Advanced manufacturing & industrial

- Refractories

- Microsilica for shaped products

Microsilica: a raw material of choice for shaped products in refractories

Refractories: meeting every challenge with a wide range of materials and formats

Refractory materials are used to provide linings in a great variety of high-temperature processing units: from 600 °C degrees in cooking ovens to over 1700 °C in hot metal treatment, via 1100 °C in petrochemical processing, 1450 °C in cement clinker sintering, etc.

Refractory materials are designed and delivered with diverse mineral and chemical characteristics and in different formats: castables, prefabricated pieces and shaped products. The latter, which this article examines, are refractory materials delivered as pieces of different sizes and shapes. These ‘building blocks’ are prefired and installed using standard masonry techniques. This differs from castables, which are batches of refractory powders prepared for direct use in their state of delivery (often transformed into monolithic or seamless refractory linings), mixed with liquids and, if required, one or several additives. Shaped products also differ from prefabricated pieces, which are moulded or precast components, often with complex forms, used for direct installation in functional parts of furnaces and kilns.

ELKEM MICROSILICA®: the quality benchmark for high-performance shaped products

The advantage of shaped products or refractory bricks is that they can be customized in terms of size and material content to adapt to temperature profiles and thermal variations, to protect against corrosion and slag, to repel melted materials in contact with the refractory lining, and to be fitted to the geometrical parameters of the shell. Shaped products also allow for a wide choice in installation processes, taking into account economic factors such as cost of materials, equipment required, labour costs, work legislation and contractual or regulatory requirements, as well as time constraints and the availability of installation skills and local service providers.

The performance of shaped products can be customized with microsilica to meet specific processing and end-product features and offer refractory manufacturers the added advantage of being pre-tested off-site to ensure they meet customer applications before installation. This allows manufacturers to choose exactly the forms they need in terms of size, format, physical performance and chemical resistance in the refractory shell, to ensure the integrity of critical parts at high temperatures and variable heating/cooling cycles, resisting chemical corrosion and mechanical stress. Shaped parts manufacturers can also use additives to improve flow of dry powder, improve densification and obtain millite/forsterite formation at high temperatures.

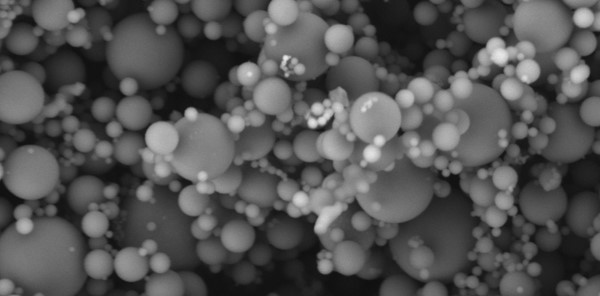

Elkem, the global leader in microsilica technology, provides a wide choice of ELKEM MICROSILICA® products for shaped parts. These customized co-products of silicon or ferrosilicon manufacturing are composed of ultrafine, amorphous spheres of silicon dioxide (SiO2) and feature high-purity properties, which can have a strong impact on the specific performance requirements of various high temperature applications.

Here is a non-exhaustive list of our product offering for the making of shaped products, many of which are also appropriate for castables (unshaped products) and prefabricated pieces. Elkem experts, technicians and sales staff are available to explore the right solutions for your specific applications:

Discover the different silicon based materials for refractory applications, each with unique properties that are specifically crafted to meet the demands of high-temperature environments.

Elkem Materials Mixture Analyser

Get the best out of Elkem's Silica fume / Microsilica material by leveraging upon our world reknown software to optimize your mixture.

More about Refractory applications

Contact us

Take your business to the next level by partnering-up with a global leading material manufacturer.