- Elkem

- Mobility & transportation

- Electrification & on-board electronics

Electrification & on-board electronics

Powering the future: embrace Sustainable mobility electrification.

We enable the mobility electrification & on-board electronics

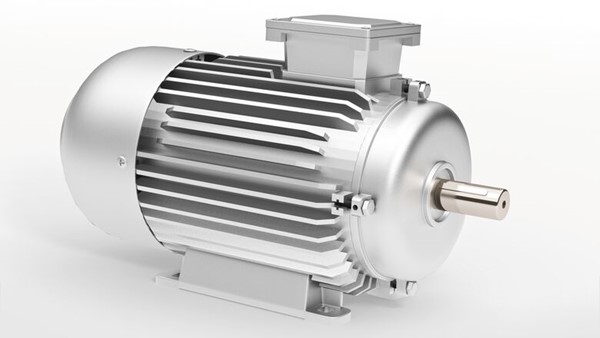

Ferrosilicon for electrical steel in EV motors

Improving the magnetic properties of electrical steel using high-purity ferrosilicon

As an alloy of iron and silicon, electrical steel (also known as silicon steel) has unique magnetic properties, which make it of rapidly increasing importance in the energy-generation sector. Our steel specialists understand the technical specifications you need to meet, and are the world leaders in developing high-purity ferrosilicon (FeSi) alloys for premium electrical steels.

Silicon for battery cells

Silicon as anode material in lithium-ion batteries

Silicon is currently used to produce e.g. SiOx, silane for different silicon morphologies and sized silicon to be used as anodes in lithium ion batteries. The reason is that silicon offer increased amount of lithium into silicon compared to graphite which increase the capacity with following increase in energy density of the final battery. There is not one solution for silicon since there are many battery technologies and applications areas for batteries. Elkem is your development partner to find the suitable silicon material for you anodes in lithium ion batteries.

Potting & encapsulation silicones to protect on-board electronics

Allow your electronics to last longer and provide better performances thanks to silicones potting and encapsulations.

Silicone potting and sealing of electronics for the automotive industry is a process of encapsulating electronic components in a protective coating. This process is used to protect components from dust, moisture, vibration, and other environmental factors that could compromise the integrity of the product. The process also offers EMI/RFI shielding, and improved product aesthetics. The silicone used in the process is typically a two-part system of an A component and a B component that, when mixed, create a fully cured silicone coating. The silicone coating is applied to the components either manually or by automated dispensing systems, and then cured at an elevated temperature. The resulting silicone-encapsulated product is highly reliable and resistant to environmental and vibration-induced damages.

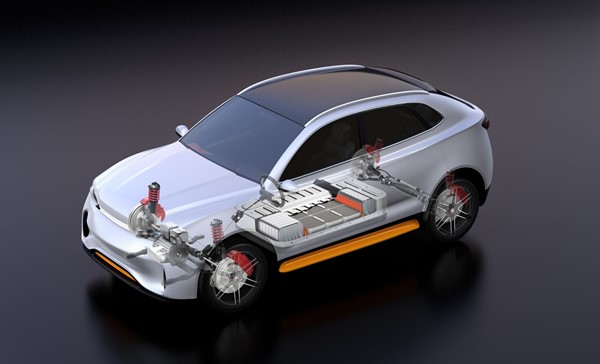

Silicone for H&EV battery pack thermal management & sealing

Silicone solutions for sealing, bonding and protecting sensitive electronic parts in H&EVs

The demand for Hybrid and Electric Vehicles (H&EV) is growing exponentially, with production generally doubling every year. It is estimated that by 2030, H&EVs on the road, will account for 15% or more of the cars in the world. As electronic and car battery technologies evolve and as the consumer demand for clean energy vehicles increase, experts consider even more H&EV on the global market [Global EV Outlook 2017]. Whatever the final figures turn out to be, all major car manufacturers have launched multiple H&EV models and have many more on the drawing boards.

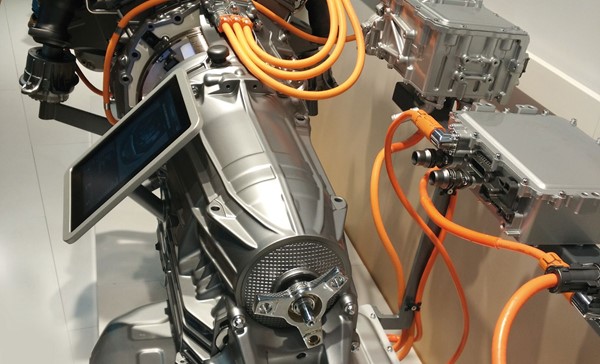

Silicone solutions for automotives cables

Silicones: the material of choice to insulate and durably protect cables in EV, HEV and ICE vehicles

Battery and cabling systems are at the heart of all automobiles, whether they are powered by traditional internal combustion engines (ICE) or are the driving force in hybrid or electrical vehicles (HEV & EV).

EV vehicles require an ever-increasing number of cables to ensure conductivity and manage temperature spikes due to a high throughput of electrical energy.

Silicon for aluminum alloying

Silicon plays a pivotal role in aluminum for vehicle electrification and on-board electronics. Silicon alloys reinforce aluminum, ensuring structural integrity in lightweight vehicle designs. This synergy between silicon and aluminum is driving the transition towards more efficient, eco-friendly, and high-performance vehicles in the era of electrification.

Lightweight battery potting & encapsulation compounds for thermal management

Power up your battery performance with lightweight potting & encapsulation compounds

Contact us

Take your business to the next level by partnering-up with a global leading material manufacturer.