- Elkem

- Mobility & transportation

- Parts manufacturing

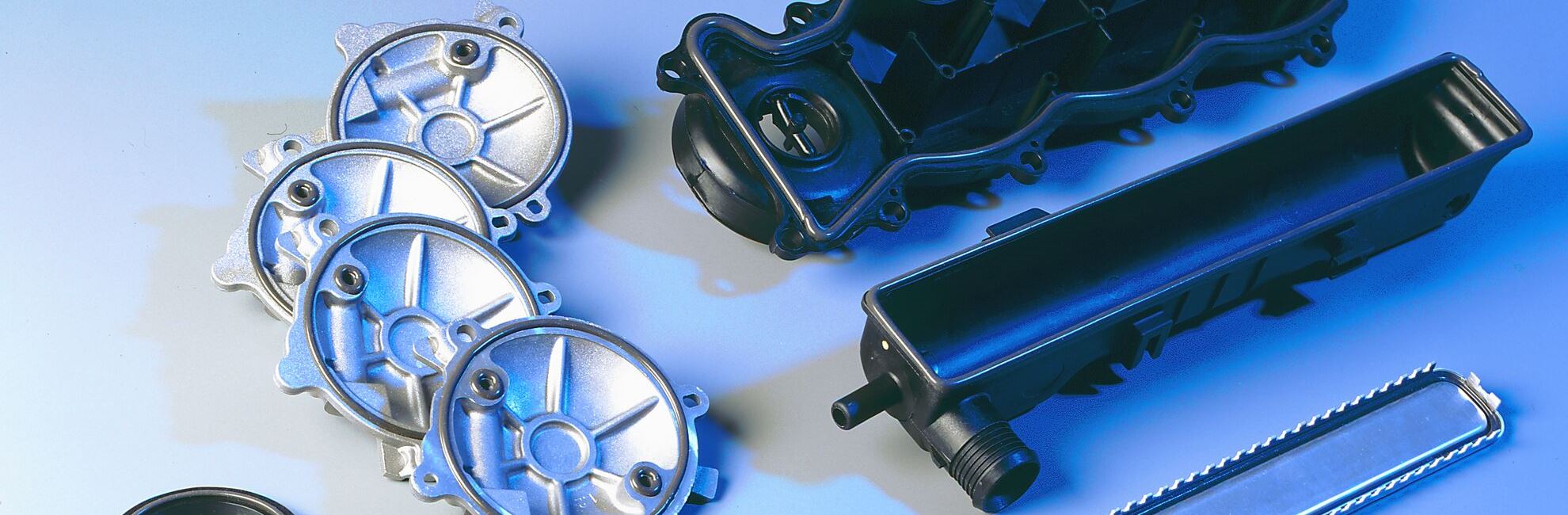

Parts manufacturing

We contribute to create stronger and more durable vehicles parts

Test carousel for external links

We provide the strength and support your vehicle needs with our high-quality metalurgical parts.

Ferrosilicon for special steel

Enhancing manufacture of special steels using high-purity ferrosilicon

The term ‘special steel’ encompasses a wide range of steel grades, and usually refers to products with a higher proportion of alloying elements, or with tailored properties for niche applications. We understand the important role that ferrosilicon (FeSi) plays in achieving these specifications, and our specialists are ready to help you choose the right product.

Silicon for aluminium brazing used in vehicles functional parts

Elkem SILGRAIN® - customized silicon materials for aluminium brazing application

Silicon a key element for enhanced aluminum brazing and great bonding

Aluminium Brazing technology is typically applied to produce heat exchangers in the automotive industry, such as radiators, and for indoor applications, such as air conditioning and refrigeration.

SILGRAIN® Braze

SILGRAIN® Braze is a tailored Silicon with homogenous quality and available in industrial volumes.

Special care is taken to closely control the particle size distribution and minimise the risk of oversize particles in our SILGRAIN® Braze product.

Foundry alloys for compacted ductile iron used in crankshaft

Controlling spheroidal graphite formation with foundry alloys

Ductile iron is a versatile material that has grown in popularity over recent decades, due to its excellent mechanical properties and castability. For these reasons, ductile iron castings are the preferred choice in many sectors, including wind energy, engineering and automotive industries.

Silicon for aluminum alloying in vehicle parts

Silicon plays a crucial role in aluminum vehicle parts manufacturing. It is a common alloying element added to aluminum to enhance its mechanical properties. When incorporated, silicon increases the alloy's strength, stiffness, and wear resistance, making it an ideal choice for automotive components.

Ferrosilicon for steel

Improving quality and performance of steels using ferrosilicon alloys

We provide the flexibility and durability your vehicle needs with our reliable elastomeric parts

Silicone rubber used in vehicles elastomeric parts

Critical automotive parts must withstand extreme conditions.

The automotive industry, which currently produces up to 80 million vehicles per year, is constantly innovating and demanding new high-performance applications, both under the hood and elsewhere in the car. These new advanced automotive parts are often designed to reduce weight and fuel consumption, thereby leading to smaller and more compact engine compartments, The reduced space results in higher temperatures and more stress to vital parts because of higher air pressure, greater water flow, more powerful fuel injection and corrosive fluids.

Silicones rubber solutions dedicated to railway parts

Make silicone elastomer solutions your next station

By 2050, the growing world’s population will reach 10 billion people, with the great majority living in or near cities. Railways will become an important constituent in the transportation mix of trains, trams and subways, both for urban mobility and intercity travel. Rail system managers and train operators are developing efficient, safe, and cost-effective railway technologies.

Industrial silicone sealant for railways

Solutions for railway rolling stock, from initial assembly to maintenance, repair and overhaul

For the last half century, the railway industry has revolutionized travel, becoming an essential mix in global transport solutions: fast-speed intercity trains, efficient regional links, urban trams, etc. Train and rolling stock manufacturers have been among the most innovative players in the transport industry, constantly seeking to improve their offer so that it meets travelers’ expectations for safe and efficient transport. Trains have also contributed to reducing the carbon imprint since they are increasingly electrically powered and have reduced urban automobile traffic by offering viable alternatives for regional and urban transportation.

Industrial assembly: sealing and bonding applications.

High quality standards silicones for industrial assembly and Electronics Protection

We provide lightweight and durable solutions with our composite parts for your vehicle's structural needs.

Silicones reusable vacuum bags composite molded parts used in transportation.

Silicone reusable vacuum bags (RVBs) for better composite infusion molding applications

Fiber reinforced polymer (FRP) composites are increasingly being used to make molded parts for a wide variety of industries: automotive (including trucks and off-road vehicles), renewable energy (components such as wind-power propellers), aerospace, marine construction, architectural structures, etc. These composites combine excellent mechanical properties with a low density, and feature high resistance to water, chemical and environmental pressure.

Thermal expansion silicones for composite molded parts used in transportation

Silicones enable accurate and cost-efficient expansion molding processes for composite materials

Composites, also known as composite materials, are fiber-reinforced resins or polymers intertwined in matrices, which are molded in expansive thermosetting processes to produce lightweight and highly resistant parts and structures.

Silicone release coating for composite liners used in aircraft manufacturing

Silicone pressure sensitive adhesives (PSA) are commonly used by composite manufacturers in the automotive industry for bonding various parts such as body panels, hoods, and spoilers. They provide an instant bond with excellent resistance to heat, chemicals, and UV radiation, allowing for a more efficient production process. PSA can be used to attach composite panels to a metal frame, bond different layers of composite material together, or attach accessories such as spoilers or body kits. It also allows for easy removal without leaving a residue, which is useful during the assembly process. In summary, silicone PSA is a versatile adhesive that is ideal for composite manufacturing in the automotive industry due to its ability to adhere to different substrates, resistance to heat and chemicals, and easy removal.

Composite Molding with silicone reusable vacuum bag

An innovative alternative to improving molded parts quality while lowering serial production costs

Contact us

Take your business to the next level by partnering-up with a global leading material manufacturer.